Concrete, Washington

Early settlers came to the Baker River in 1871, originally calling the settlement on the west bank “Minnehaha.” Concrete Washington History began in 1890, when the town-site was platted by Magnus Miller. A post office was set up, and the name “Baker” was adopted.

On the east bank of the river, the community that sprang up around the Washington Portland Cement Company (1905) was named “Cement City.” After the Superior Portland Cement Company plant was built in Baker in 1908, local leaders decided to merge the two towns, and in 1909, after much discussion, the new community settled on the name “Concrete.”

Limestone is a sedimentary rock composed primarily of calcium carbonate that is commonly used to create concrete. To make concrete from limestone, the rock must be heated in a kiln until it becomes quicklime. This quicklime is then mixed with water and other materials, such as sand and gravel, to form concrete. The chemical reaction that occurs during this process, known as hydration, creates a strong, durable material that is widely used in construction. Additionally, because limestone is plentiful and relatively inexpensive, it is a popular choice for concrete production around the world. Concrete from this site was excellent and used to build Seattle skyscrapers and the Grand Coolee dam. The Roman Pantheon, dating to the 2nd century AD, is a circular concrete building faced with brick, boasting the world's largest and oldest unreinforced concrete dome. The Romans made superior concrete by mixing lime and volcanic rock.

Towers in Concrete, WA

T he lower floor of the concrete plant, with holes for the crushers

train from Concrete

the town fo concrete over 60 years ago

Concrete movie theater over 70 years ago -- across from the current theater. This photo is from the Concrete Heritage Museum.

One of the kilns for heating limestone This pic is from Men of Concrete; despite mail, email, and phone attempts to get official permssion, I have not been able to reach the publisher. If they have objections, I will gladly take the picture down.

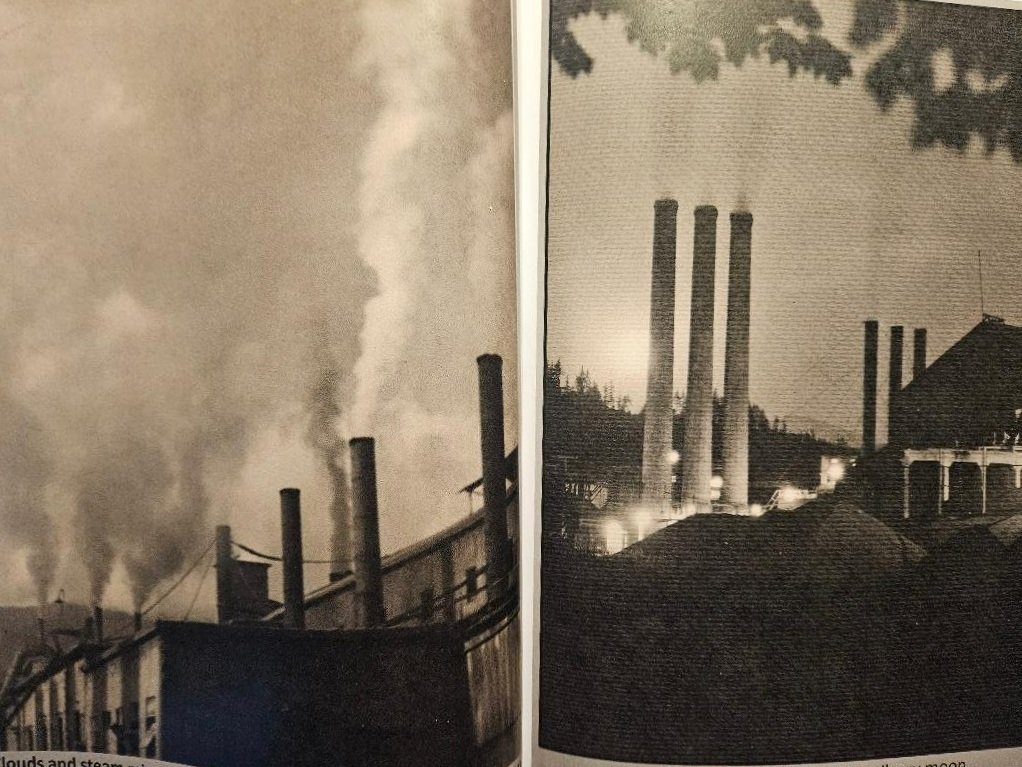

shots of the Superio Cement plant when it was operating a full capacity This pic is from Men of Concrete; desite mail, email, and phone attempts to get official permission, I have not been able to reach the publisher. If they have objections, I will gladly take the picture down.

Wide shot of Concrete, Washintgon. This pic is from Men of Concrete; desite mail, email, and phone attempts to get official permssion, I have not been able to reach the publisher. If they have objections, I will gladly take the picture down.

These are two more kilns for heating limestone. This pic is from Men of Concrete; despite mail, email and phone attempts to get official permssion, I have not been able to reach the publisher. If they have objections, I will gladly take the picture down.

Mining limestone in the quarry near the concrete plant - from the Concrete Heritage Musuem

For more information, visit the Concrete Heritage Museum —https://www.concreteheritagemuseum.org/